Excitement About Stainless Steel Infill Panel

Table of ContentsFascination About Stainless Steel Infill PanelOur Stainless Steel Infill Panel Diaries

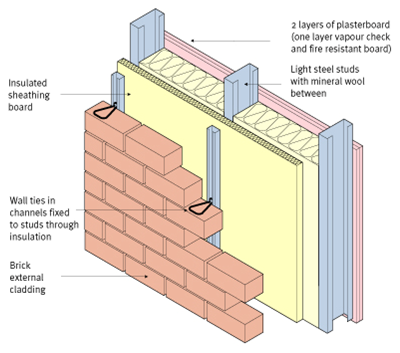

Insulated infill panels normally are composed of an exterior and interior skin (aluminum or steel) laminated to any type of range of substrates. These substrates/skins then sandwich a protecting core to provide you a 5-ply panel all set to be glazed into the structure. One of the most generally used substratum is tempered hardboard, which has actually been considered an industry standard for greater than half a century. Nonetheless, over the last twenty years, there has actually been a rise in other substrate products. These include, but are not restricted to: Fiber Reinforced Cement Board (which is a Class A, non-combustible product) Corelite (or corrugated plastic, a light-weight material that supplies a greater degree of moisture resistance) Plaster Board (which is utilized to fulfill fire codes when utilized as the interior substrate) And also most just recently, solid plastic (or ABDOMINAL MUSCLE board).

The functions of an infill panel are as noted previously for cladding panels as a whole. Infill panels are light-weight and also generally glazed to give good internal natural day illumination problems. Various from cladding wall surface because infill panels is taking care of in between framework in the mounted structure. The panel layout can be so organized to subject some or all of the structural members developing various optical perceptions. For instance, if straight panels are made use of, leaving just the light beams subjected, an impression of additional length and/or minimized elevation can be developed. The style demand infill panel wall surfaces are:1) lightweight2) resistance to fire3) warmth loss4) high durability5) rigid6) less maintenance7) audio penetration8) interstitial condensation A vast variety of materials or mixes of materials can be utilized such as lumber, steel, light weight aluminum as well as plastic.

The glazing component need to be such that an affordable thickness of glass can be defined (stainless steel infill panel). The jointing problem with infill panels take place generally at its junction with the structural framework as well as allowance for dampness or thermal activity is usually accomplished by utilizing an appropriate mastic or sealer. Stonework infill panels of modern dental caries construction can be used to maintain traditional features and also to achieve high requirements of sound and thermal insulation and fire protection. Masonry walls are connected to the structural framework with wall surface ties cast right into the concrete columns or with a purpose-made cladding assistance system. The majority of infill panels are provided important source as a manufacturer's modular system, since purpose-made panels can be uneconomic, yet whichever approach is selected the layout intends stay continuous; that is, to offer a panel which fulfils all the called for functions as well as has a low long-term upkeep aspect.

One of the maintenance troubles run into with infill panels and also most likely to a lesser level with the concrete cladding, is the cleansing of the faade and specifically the glazing. All buildings collect dust, the impacts of which can vary with the product: concrete as well as masonry have a tendency to accept dust as well as weather all-natural, whereas invulnerable products such as metals and also glass do not approve and also can corrode or come to be much less efficient. If glass is permitted to end up being coated with dust its aesthetic look is less appropriate, its optical efficiency minimizes considering that clearness of vision is lowered and the beneficial penetration of all-natural daylight pop over to these guys lessens.

Examine This Report about Stainless Steel Infill Panel

Access for cleaning polished areas can be exterior or interior. Windows at ground level present no access troubles and also existing just the inquiry of option of approach such as hand cloths or telescopic poles with squeegee heads. Low as well as medium-rise frameworks can be gotten to by ladders or a mobile scaffold tower and also usually present extremely couple of problems. High-rise structures need careful consideration. Outside access to home windows is gained by utilizing a cradle suspended from roofing degree; this can be in the kind of a temporary system including counterweighted cantilevered beam of lights from which the cradle is suspended. Permanent systems, which are incorporated as part of the building style, are more efficient and also consist of a track on which a mobile cart is mounted as well as from which davit arms can be forecasted beyond the roof covering side to sustain the cradle.

Inner accessibility for cleaning up the outside glass face can be attained by making use of home windows such as relatively easy to fix sashes, straight as well as upright moving sashes, but the designer is limited More Help in his selection to the reach feasible by the typical individual. It can not be exaggerated that such home windows can be a really harmful hazard unless carefully designed so that all parts of the polished location can be gotten to by the person cleansing the home windows while standing strongly on the floor. Intro The functions of an infill panel are as listed formerly for cladding panels generally. Infill panels are light-weight as well as generally glazed to give excellent internal all-natural day illumination problems (stainless steel infill panel).